doi: 10.62486/agma202427

ORIGINAL

Working conditions and health effects of workers in a microware manufacturer of medical furniture, Maracay 2019

Condiciones de trabajo y efectos a la salud de los trabajadores en una microempresa de fabricación de mobiliario médico, Maracay 2019

Nelyerliz Suarez1 ![]() , Mauro Páramo1

, Mauro Páramo1 ![]() , Carmen Rodríguez1

, Carmen Rodríguez1 ![]() , Misael Ron1

, Misael Ron1 ![]() *, Estela Hernández-Runque1

*, Estela Hernández-Runque1 ![]()

1Instituto de Altos Estudios “Dr. Arnoldo Gabaldon”. Venezuela.

2Universidad de Carabobo. Venezuela.

Cite as: Suarez N, Páramo M, Rodríguez C, Ron M, Hernández-Runque E, Working conditions and health effects of workers in a microware manufacturer of medical furniture, Maracay 2019. Managment (Montevideo) 2024; 2:27. https://doi.org/10.62486/agma202427

Submitted: 10-11-2023 Revised: 12-03-2024 Accepted: 18-06-2024 Published: 19-06-2024

Editor: María

Belén Lozano García ![]()

Corresponding Author: Misael Ron *

ABSTRACT

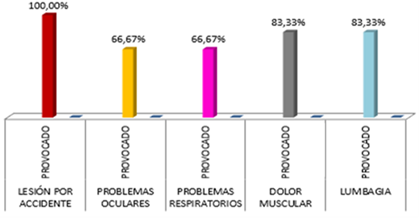

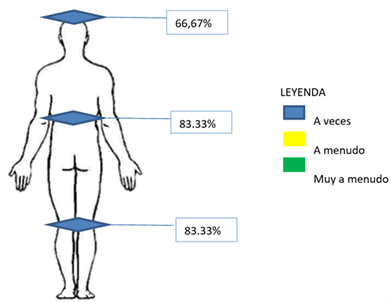

The present study aimed to determine the working conditions and health effects of the workers of a medical furniture manufacturing microenterprise. For this purpose, a quantitative and descriptive research was carried out, applied to 6 workers, the data collection technique was based on non-participant structured observation to know the work process and a structured interview in which the guide questionnaire was applied Colombian technique 450 to identify risk factors, their level and acceptability. To recognize the health effects, the questionnaire on risks and damages by Pere and Laurent was applied with the body diagram of pain. The hazardous work processes identified were: inadequate lighting, sharp objects, moving machines and tools, particle projection, welding smoke, wood dust, vibrations, gases and vapors, lifting and transporting loads, inappropriate positions. The risk factors identified were: physical and chemical with a level of risk III being acceptable, as well as dysergonomic and mechanical with a level of risk II being not acceptable, likewise the health conditions identified were injuries by accident, eye and respiratory problems and muscle aches, the most frequent areas of pain being legs, neck and lumbar region.

Keywords: Working Conditions; Safety; Prevention and Health Effects.

RESUMEN

El presente estudio tuvo objetivo determinar las condiciones de trabajo y efectos a la salud de los trabajadores de una microempresa de fabricación de mobiliario médico. Para tal fin se realizó una investigación cuantitativa y descriptiva, aplicada a 6 trabajadores, la técnica de recolección de datos se basó en la observación estructurada no participante para conocer el proceso de trabajo y una entrevista estructurada en la que se aplicó el cuestionario de la guía técnica colombiana 450 para identificar los factores de riesgo, el nivel y aceptabilidad de los mismos; para reconocer los efectos a la salud se aplicó el cuestionario sobre riesgos y daños de Pere y Laurent con el esquema corporal del dolor. Los procesos peligrosos de trabajo identificados fueron: iluminación inadecuada, objetos punzocortantes, máquinas y herramientas en movimiento, proyección de partículas, humo de soldadura, polvos de madera, vibraciones, gases y vapores, levantamiento y transporte de cargas, posiciones inadecuadas. Los factores de riesgo identificados fueron: físicos y químicos con un nivel de riesgo III siendo aceptable, así como disergonómico y mecánicos con un nivel de riesgo II siendo no aceptable, asimismo, las afecciones a la salud identificadas fueron lesiones por accidente, problemas oculares y respiratorios y dolores musculares, siendo las zonas de dolor más frecuentes piernas, cuello y región lumbar.

Palabras clave: Condiciones de Trabajo; Seguridad; Prevención y Efectos a la Salud.

IntroducTiOn

Work is considered a means through which the individual acts with the environment to obtain the goods and services necessary to satisfy his or her needs and is considered a social determinant of the health-disease process, which can be favorably or unfavorably influenced. Hence, occupational health and healthy work environments are among the most precious assets for individuals, communities, and countries. A healthy work environment is essential for the health of workers and for making a positive contribution to productivity, work motivation, work spirit, job satisfaction, and overall quality of life.(1,2,3,4)

However, there are events such as occupational accidents and work-related diseases that disrupt these healthy work environments and are becoming more and more frequent worldwide. Globally, figures indicate that the number of people dying from work-attributable causes grew from 2,33 million in 2014 to 2,78 million in 2017.(2,5,6,7,8)

According to these figures, worldwide, work-related deaths have increased despite the underlying underreporting of these data. This situation reveals an alarming reality that has been paradoxically worsening with the advancement of science and technology. Likewise, and following in the international context, the most frequent pathologies related to occupational risk factors are musculoskeletal disorders, followed by auditory pathologies, and the main causes of work-related mortality in the world are mainly related to occupational cancer, followed by work-related cardiac diseases and, in third place, occupational accidents.(9,10,11,12)

Additionally, according to data from a study conducted by the National Institute of Safety and Hygiene at Work (INSHT) in 2018 on working conditions, 32 319 occupational accidents were reported in the activity corresponding to the metal sector. Similarly, this report notified 5 080 occupational accidents in the activity corresponding to the wood and cork industry.(3,13,14,15)

In this regard, according to data provided by the National Institute of Occupational Safety and Health (INSST) in its annual report of occupational accidents in Spain for 2018, in the wood and cork sector, there were 7 548 accidents, and in the metal sector, 8 399 occupational accidents.(3,16,17,18)

In Venezuela, according to data from the National Institute of Prevention, Occupational Health and Safety (INPSASEL), in 2013, 39 321 occupational accidents were reported. According to figures from this same institute, for 2013, 62 375 were reported in Aragua state and 86,102 occupational accidents in Carabobo, with the most frequent accidents being struck by objects with a total of 59 043 cases and contact with a sharp, pointed, hard, rough material agent with 58 734 reported cases. Likewise, the total number of reported cases of occupational diseases reached 10 625 in 2013, noting that most of the reported diseases are related to musculoskeletal disorders, with a total of 10 366.(4,19,20,21)

From this perspective, working conditions and environment include any circumstantial aspect in which the work activity occurs, both factors of the physical environment in which it is performed and the temporary circumstances in which it occurs. These working conditions and environment are also considered a determinant factor of the health-disease processes in the working population. Considering that the relationship between health and work is very close, it is important to consider that it can be detrimental to health when work is not performed under adequate conditions and in an environment. Therefore, Article 11 of the Partial Regulation of the LOPCYMAT (2007) states that working conditions are “the general and special conditions under which the execution of tasks is carried out,” Thus, working conditions include environmental, technological, organizational, and work organization aspects.(5,22,23,24)

Depending on the working conditions and environment, the existence of risk factors can be found, these being defined as that working condition, which, when present, increases the probability of occurrence of that damage and, when it is present, demonstrates the absence of an appropriate control measure, these risk factors, which in Venezuela are also called agents, are classified into physical, chemical, biological, mechanical, dysergonomic, psychosocial and meteorological. As described by Neffa (2015), working conditions (resulting from sociotechnical and organizational factors) can compensate for or intensify these risk factors, being relevant to creating adequate conditions for work performance for the benefit of workers’ health.(6,25)

In the work center under study, there is a need to study the working conditions and environment as well as to recognize the risk factors to which workers are exposed daily since, given the absence of their identification, workers have presented multiple rests due to musculoskeletal discomfort, and on some occasions, occupational accidents have occurred, which could be due to ignorance of the proper use of personal protective equipment for the handling of machinery.

Due to those above, the present research is proposed, whose objective was to determine the working conditions and effects on workers’ health in the microenterprise of medical furniture manufacturing, Maracay 2019.

METHOD

This research was framed within the quantitative paradigm, with a descriptive and cross-sectional field design. The population consisted of 6 workers from the microenterprise production areas that manufacture medical furniture. The sample consisted of 6 male workers with the positions of welder, carpenter, upholsterer, seamstress, general assistant, and administrative assistant. The sampling was of the census type since it is a small company with one worker for each area, and the study encompasses all the company's departments.

The data collection technique was based on structured non-participant observation to learn about the production process of the microenterprise, with the elaboration of a scheme of the same and the application of a questionnaire of the Colombian technical guide 450 (guide for the identification of hazards and risk assessment in occupational safety and health)(7) this guide provides.

· Guidelines for the subjective identification by the evaluator of the hazards associated with the activities in the workplace.

· Taking into account physical, biological, dysergonomic, psychosocial, chemical, and mechanical agents.

· Assessing the level of risk derived from them.

Likewise, once the data was obtained subjectively, the quantitative assignment of each variable by risk factor was carried out to determine the level of risk and level of acceptability of the same; for this purpose, the level of risk (NR) was calculated, which corresponds to the process of determining the probability of occurrence of specific events and the magnitude of their consequences, using the following formula of the guide: NR = NP x NC, where NP = Probability level and NC = Consequence level. In turn, to determine the NP, it was necessary to use another formula where NP = ND x NE, which means ND = Deficiency Level NE = Exposure Level.

To determine the level of deficiency, level of exposure, and level of consequence, several tables of the Colombian Technical Guide 450 were used, where the parameters for each of them and their score are detailed, allowing the conversion of the data. It is important to emphasize that one of the virtues of this instrument is that it allows the researcher who does not have the measuring instruments to make an objective evaluation and analyze them subjectively under scientifically proven parameters.

With the data obtained through the application of this instrument, we determined the level of risk (table 1) and the level of risk acceptability (table 2). It should be noted that in comparison with other instruments, the lowest risk level is denoted with the number that expresses the highest value (IV acceptable), and the scale degrades to I, where the most harmful working conditions are manifested.

|

Table 1. Meaning of risk level |

||

|

Risk level |

Value of NR |

Meaning |

|

I |

4 000 – 600 |

Critical situation. Suspend activities until the risk is under control. Urgent intervention. |

|

II |

500 – 150 |

Correct and take control measures immediately. However, suspend activities if risk level is above or equal to 360. |

|

III |

120 – 40 |

Improve if possible. It would be advisable to justify the intervention and its cost-effectiveness. |

|

IV |

20 |

Maintain existing control measures, but solutions or improvements should be considered and periodic checks should be made to ensure that the risk is still acceptable. |

|

Source: Colombian Technical Guide for Hazard Identification and Risk Assessment (2010)(7) |

||

|

Table 2. Risk acceptability level |

|

|

Level |

Meaning |

|

I |

Not acceptable |

|

II |

Not acceptable or acceptable with specific control |

|

III |

Acceptable, with room for improvement |

|

IV |

Acceptable, with periodic review |

|

Source: Colombian Technical Guide for Hazard Identification and Risk Assessment (2010)(7) |

|

In the same way, a structured interview was used to determine the effects on workers' health, in which two instruments were applied: the questionnaire on risks and damages of the guide for a union intervention by Pere et al.(8) which shows a list of injuries and illnesses that the workers marked if they occurred or not and the relationship that the workers considered to exist with the working conditions (caused or aggravated by the same), this questionnaire gives importance to the perception that the worker has of the working conditions and the relationship that he considers of the same with the presence of accidents and illnesses. In addition, a body schema of pain was applied as a complement to know the effects on health, where the workers indicated the sites of pain or discomfort that occurred at the end of the work week and their frequency.

The data analysis was descriptive, using absolute and percentage values expressed in tables and figures. For ethical purposes, an informed consent form was prepared, in which the employer and the workers were informed of the study's objectives, and the justification, benefits, procedures, and risks were explained; this document was read and signed by the study participants.